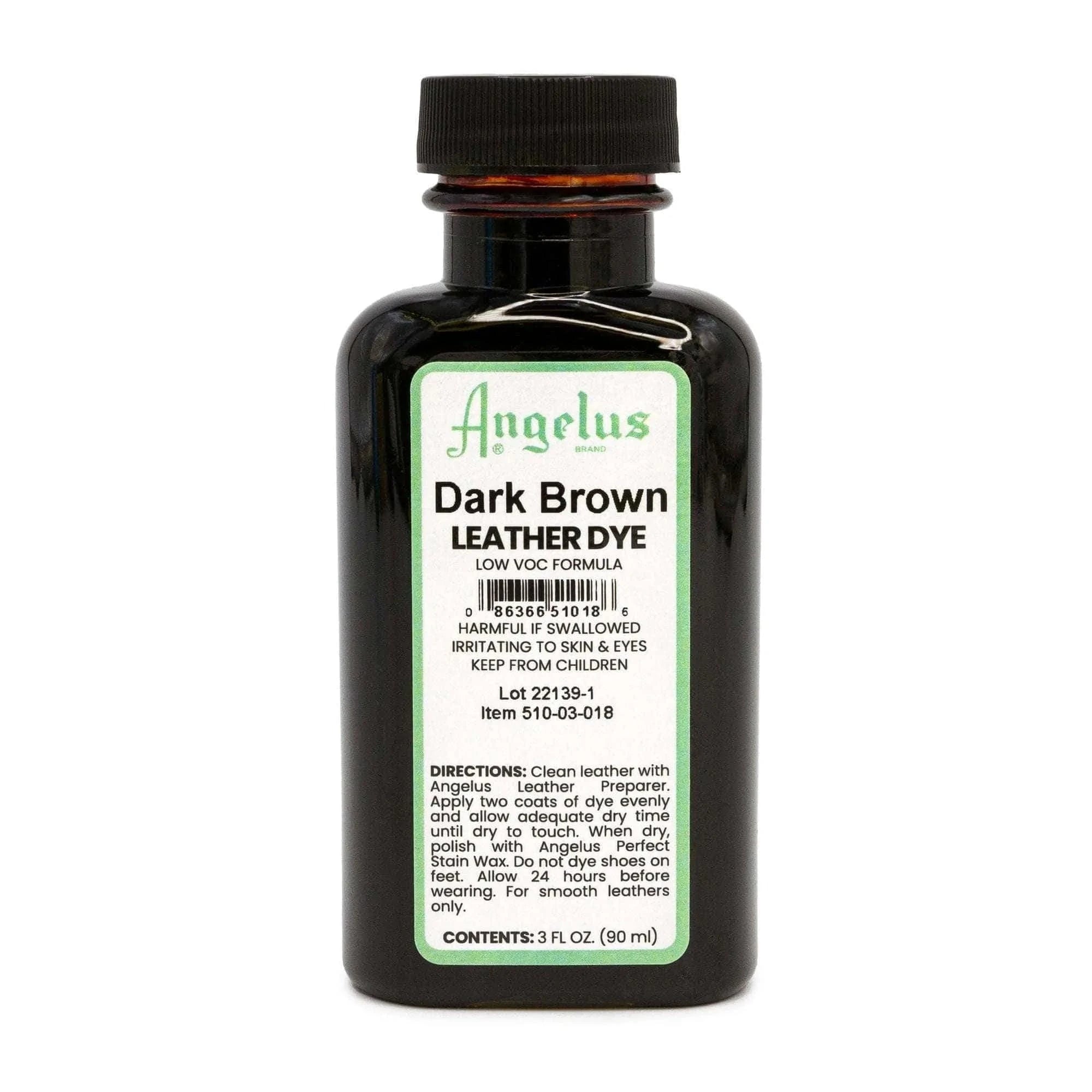

Quick Guide to Leather Dye

Why Choose Low-VOC Leather Dye?

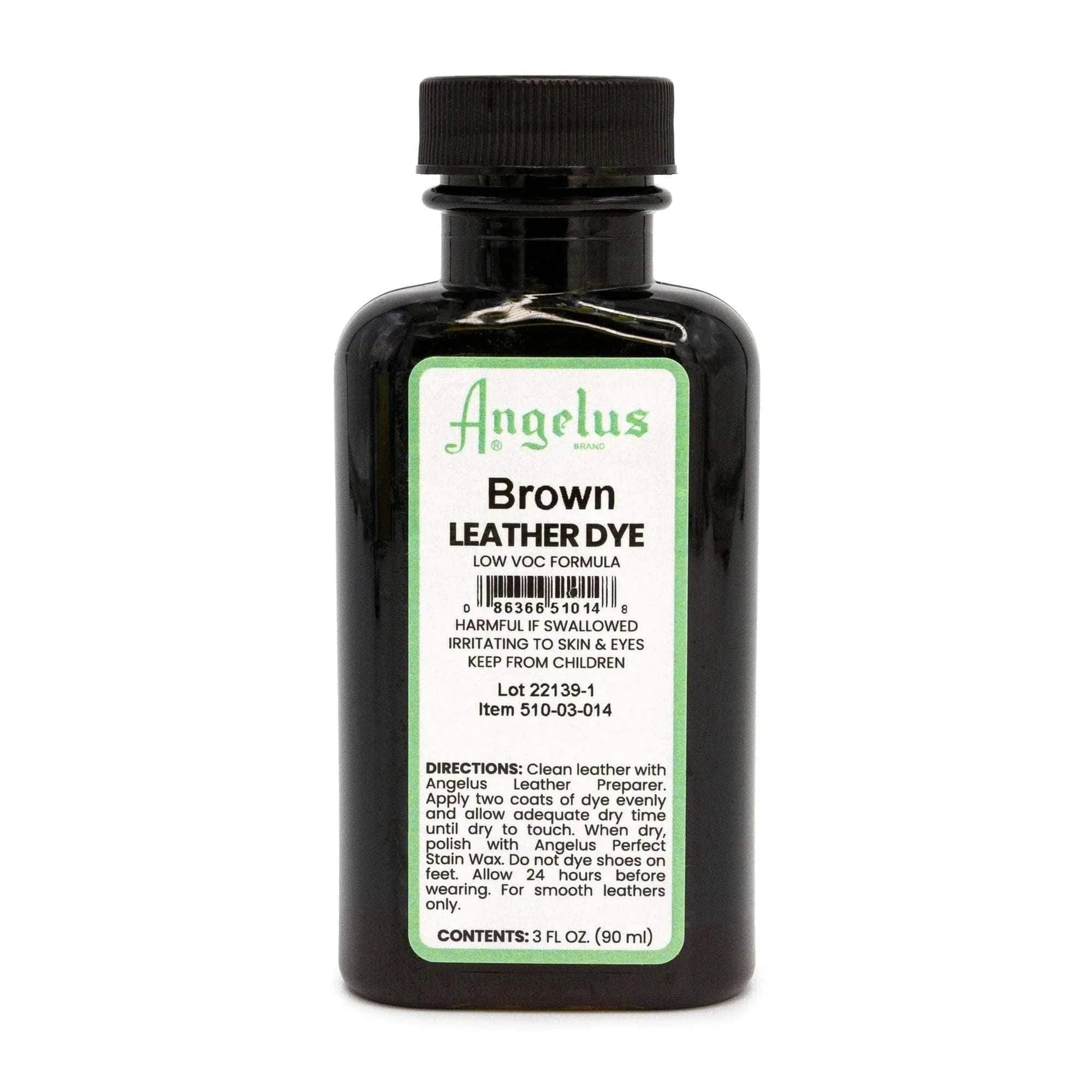

Our low-VOC leather dyes provide vibrant color and a safer, eco-friendly formula, making them perfect for professional results without harsh chemical smells.

Here’s more on why creators who care about comfort and quality choose our dyes.

-

Safer for You and Your Space: Our low-VOC formula has fewer volatile organic compounds, so you can breathe easier and stay focused on your project without worrying about strong fumes.

-

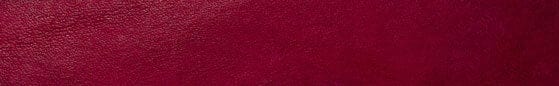

Superior Color and Durability: The dye absorbs deeply and evenly, giving all leather items, from shoes to bags, a rich, lasting color.

-

Eco-Friendly Choice: The non‑flammable formula meets California’s chemical standards and ships worldwide. You can keep it handy with zero hassle.

-

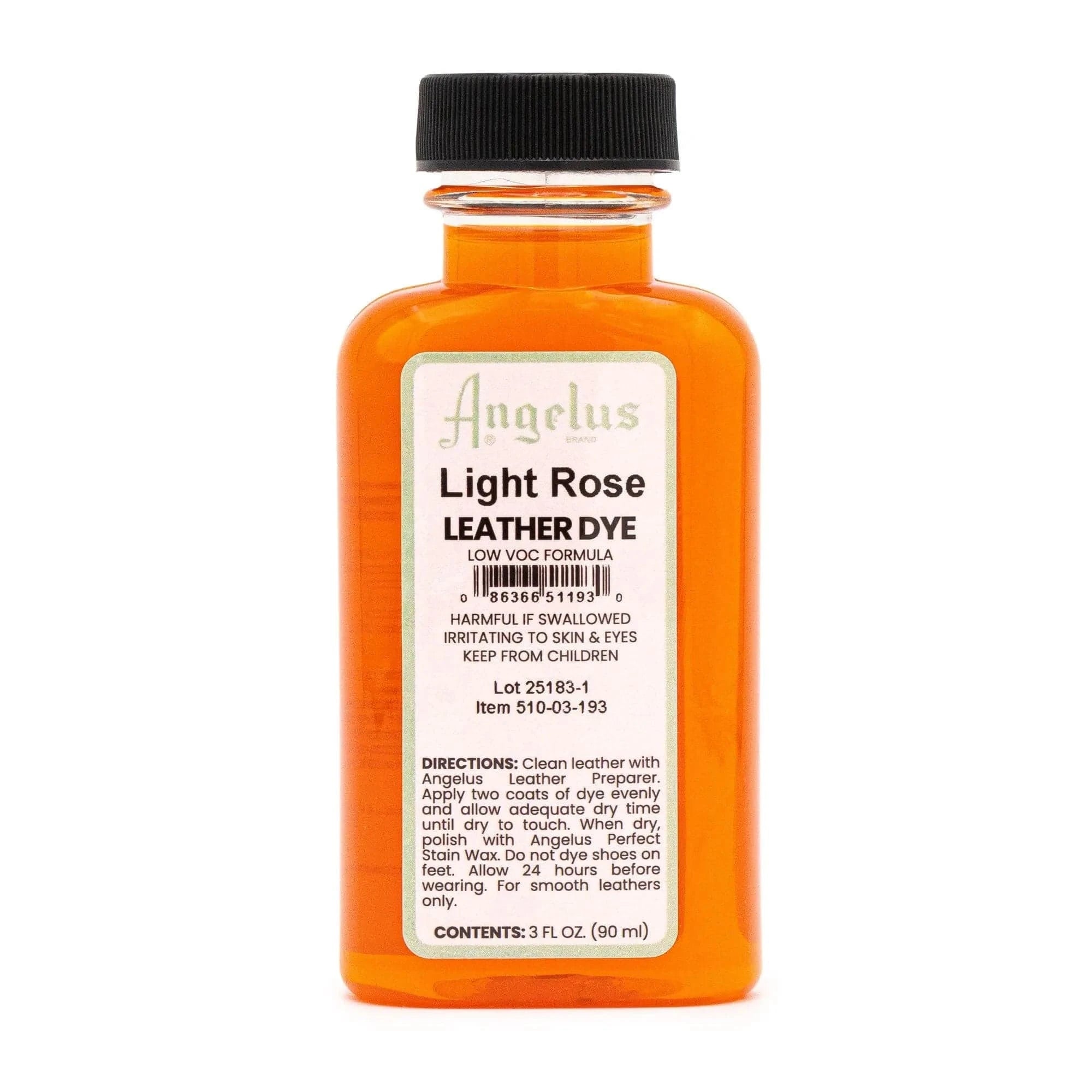

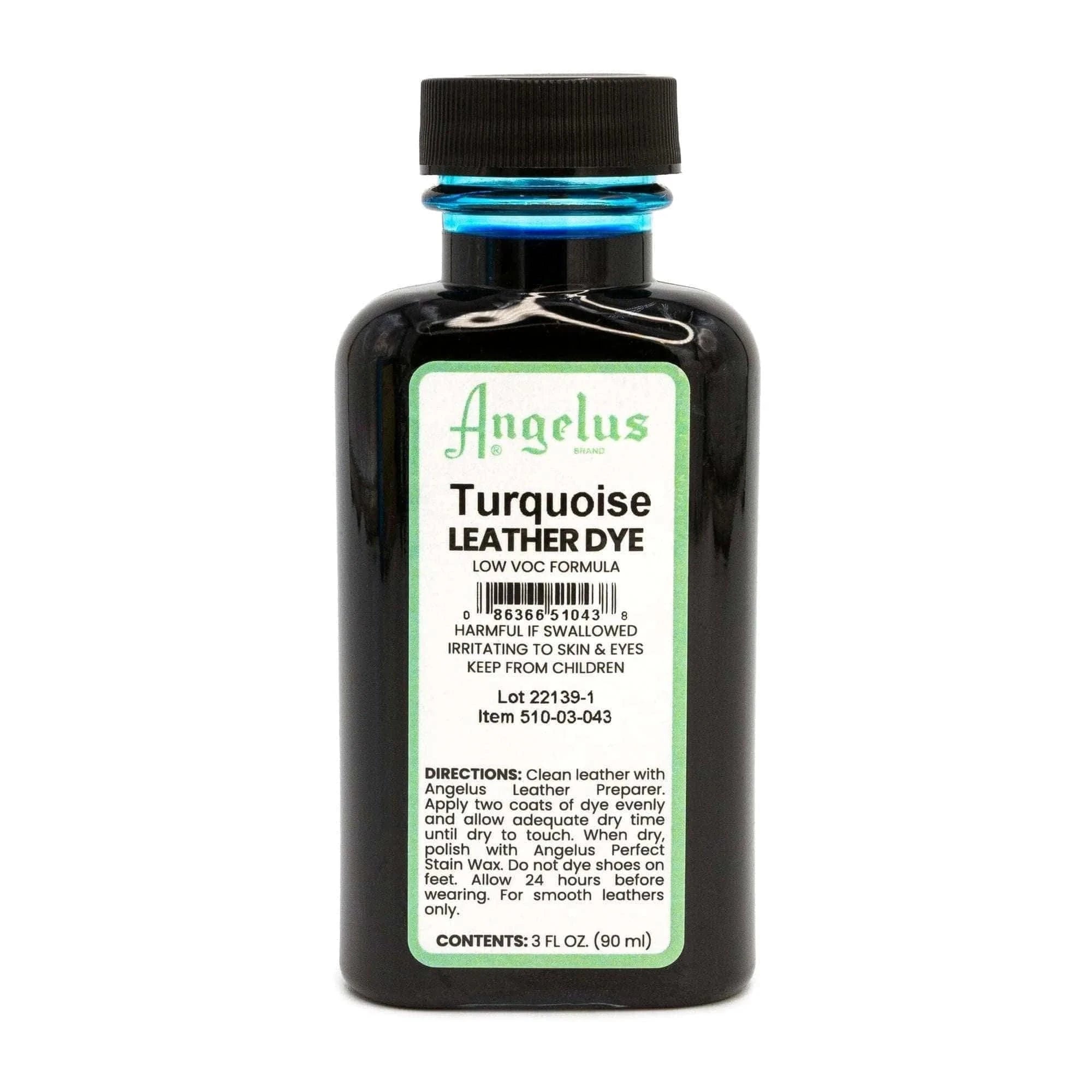

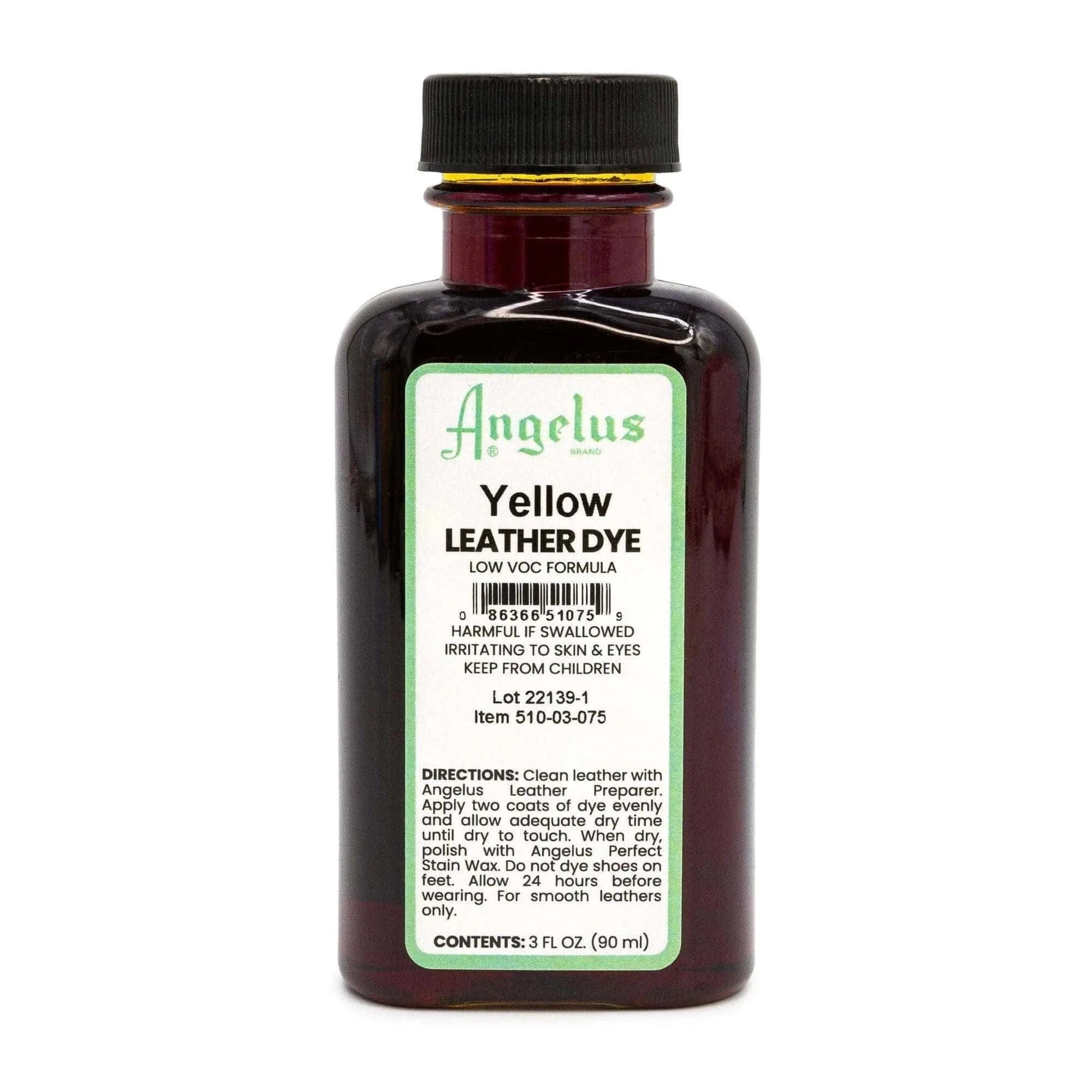

Available in a Wide Palette: Angelus Brand offers over a dozen classic shades perfect for sneaker customizers, collectors, and anyone who values a professional finish.

-

Made for Versatility: Whether you're working on bags, belts, jackets, or furniture, this dye adapts to any smooth leather surface for pro-level results.

Specifications & Comparison

Let's quickly compare Angelus Low-VOC Leather Dye with our traditional leather dye. Understanding the differences will help you choose the best option for your project and workspace.

|

Feature |

Low VOC Leather Dye |

Traditional Leather Dye |

|

VOC Levels |

Fewer fumes and safer to use indoors |

Stronger smell; recommended for open spaces |

|

Color Quality |

Rich, long-lasting color that soaks into the leather |

Bold color that also penetrates deeply |

|

Drying & Curing |

The product dries a bit slower due to the absence of alcohol. Typically, it takes 10–25 minutes per light coat and 24 hours to fully cure. |

Regular leather dye dries faster (about 10 minutes max), so you can seal and finish sooner. But waiting 24 hours for a full cure still gives the best results. |

|

Use Case |

Ideal for contemporary crafters seeking performance with a focus on safety and environmental responsibility. |

Widely used by professionals and hobbyists for vibrant projects where strong dye penetration is key. |

|

Color Penetration |

Deep fiber penetration for long-lasting, even results |

Strong absorption and fast saturation |

|

Compliance |

Meets strict modern air quality standards, including California regulations. |

Meets industry standards but generally higher in VOCs. |

How to Use Low-VOC Leather Dye

Nailing the dye process boils down to these simple, smart steps.

-

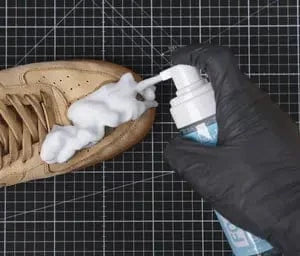

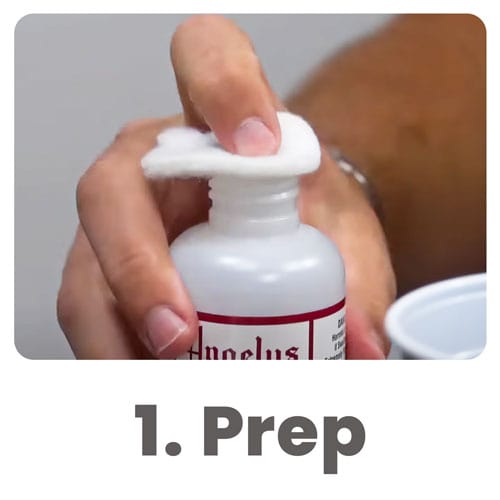

PREP. Start with a clean surface. Clean your leather with our Leather Preparer and Deglazer. This removes oils and old finishes so the dye absorbs evenly. Then, let it dry.

-

DYE. Using a wool dauber, brush, or airbrush, apply the dye in thin, even coats. Work in small sections to prevent the dye from drying before you can work it in.

-

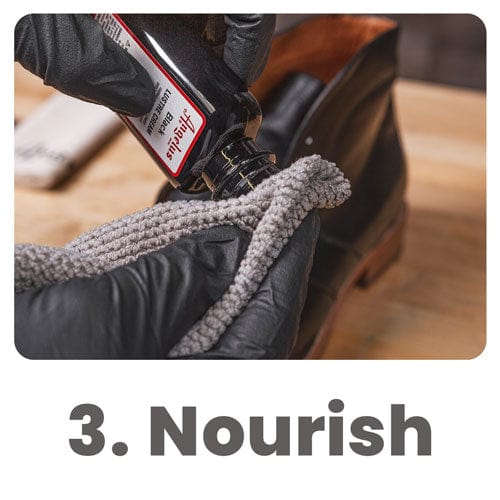

NOURISH. Pause 10–25 minutes before adding another coat. Once fully cured (around 24 hours), apply Lustre Cream or Acrylic Finisher for protection and a smooth finish.

-

BUFF. Gently buff the finished surface. This evens out the texture and helps reduce dye transfer.

Expert Tips for Best Results

Getting that perfect, lasting color with Low VOC Leather Dye is easier when you follow a few pro tips. These simple tips will help your project pop and stand the test of time.

-

Practice on Scrap Leather. Before starting your main project, test the dye on a small hidden area or scrap first to see how the color looks and feels on that material.

-

Always Prep Your Surface. Never skip the prep step. A clean surface is a must for a professional finish. It ensures the dye absorbs evenly and prevents the dye from peeling or flaking later on.

-

Layering Colors. After the first coat dries, layer colors to create custom shades, but ensure each layer is fully dry to prevent muddying the colors.

-

Seal for Longevity. A final sealant is your best friend. A good Acrylic Finisher will protect your dye work from scratches, water, and everyday wear and tear.

-

(Optional) Get Personalized Advice. Get personalized advice through Angelus Brand’s video tutorials or live chat support for expert help. We're here to help you succeed.

Frequently Asked Questions

What is low-VOC leather dye?

Low-VOC leather dye is a type of dye that releases far fewer harmful volatile organic compounds than traditional dyes but still deeply penetrates leather for lasting, vibrant color.

How long does it take for low-VOC leather dye to dry?

As a rule of thumb, wait about 10-25 minutes between light coats to let each layer dry. Allow the piece to cure completely for 24 hours before applying a sealer or using the item.

What kind of dye is best for leather?

A non-alcohol-based penetrating dye, like Angelus Low VOC Leather Dye, is ideal for smooth leathers such as cowhide. It soaks into the grain to deliver rich, long-lasting color that flexes with the material and doesn’t crack or peel over time. For other types of leather like nubuck and suede, use tailor-made suede dyes.

Should you wet leather before you dye it?

No. After using Leather Preparer & Deglazer, allow the leather to dry completely. Wait a few minutes to ensure it’s dry, as water can dilute the dye and cause blotches.

Other collections and products:

White Leather Paint | Pearlescent Paint | Shoe Laces | Leather Dye | Suede Dye | Shoe Cleaner | Shoe Wax | Rope Laces | Shoe Polish | Dye Products | Shoe Customization Kit | Shoe Paint Kit | Mink Oil | Midsole Paint | Paint Duller | Angelus 2 Soft | Fabric Dye | Urethane Clear Coat | Angelus Best Sellers