⚠️Leather Dyes can’t ship to California or out of USA⚠️

For alternative try our Low VOC Dye

Quick Guide to Leather Dye

Why Shop Our Leather Dye Range?

At Angelus Direct, our leather dye range is built for both precision and performance. Each alcohol-based leather dye penetrates deeply into the material, delivering bold, lasting color that dries uniformly.

Additionally, the formula mixes easily, enabling you to create interesting middle tones or a custom color that precisely meets your needs. For those seeking a cleaner application, low-VOC pro dye options are also available.

Whether you are restoring leather boots or refreshing worn furniture, every bottle is made for quality and consistency. With fast U.S. shipping, your online order arrives right when you need it.

Dye vs Paint: Which Is Right for You?

Understanding the difference between leather dye and paint helps you choose the right approach for your project.

Leather dye penetrates the fibers, allowing the color to become part of the material. This makes it an excellent choice for restoring leather items, such as belts, boots, and furniture, where flexibility and a natural finish are important.

In contrast, leather paint forms a surface layer, providing bold, solid coverage that is ideal for custom artwork or intricate designs. If you want to change the color while retaining the texture, dye is the better option.

However, if your goal is to cover scratches or create vibrant patterns, paint may be a more suitable option. Consider your finish preference and how the item will be used.

Types of Leather Dye

Not all leather dyes perform the same, so choosing the right type depends on your setup and project goals.

Alcohol-based leather dye is ideal for fast drying, deep penetration, and intense color. It works well for leathercraft, footwear, and projects that require multiple layers or custom color mixing.

If you are working indoors or prefer a lower-odor option, a low VOC leather dye may be the better choice. These low-VOC dyes offer safer handling and excellent fiber bonding, making them suitable for longer sessions or enclosed spaces.

By understanding how each dye behaves, you can confidently select the best option for your leather items.

How to Choose the Right Dye for Your Project

To get the best results, match your leather dye to the material, original color, formula type, and flexibility requirements.

Leather Type & Finish

Different types of leather respond to dye in various ways. Full-grain and top-grain leather absorb dye evenly, resulting in a rich, smooth finish. These types are ideal when you want consistent color across the surface.

In contrast, suede and nubuck are more delicate and absorb dye quickly. To achieve consistent results, apply light coats and gradually build up the color. For these softer textures, use a suede dye explicitly designed for absorbent finishes.

Base Color & Desired Shade

The starting color of your leather affects how the final shade appears. Darker dyes cover lighter bases more effectively and produce stronger results.

If your leather is light, applying certain shades may lead to unexpected undertones. To avoid surprises, test your chosen dye on a hidden area or use a leather test swatch before making a commitment. This step allows you to preview the outcome and adjust the shade if needed.

Dye Formula Selection

Each dye formula offers different benefits. Alcohol-based leather dye dries quickly and delivers intense color, which is ideal for making bold changes. However, it has a stronger odor and may dry out the leather if not followed by conditioning.

On the other hand, low-VOC or water-based dyes work more slowly but offer deeper penetration and a gentler finish. These are well-suited for indoor use and more sensitive environments.

Flexibility & Scuff Resistance

Footwear and other high-use leather goods need dyes that can handle bending, rubbing, and daily wear. In these cases, alcohol based leather dye is a strong choice because it penetrates deeply and holds color well.

After applying the dye, use a leather conditioner to maintain softness and prevent cracking. Then, seal the surface with a topcoat to improve resistance to scuffs and surface damage.

This layered approach helps preserve the look and feel of your leather over time, especially in frequently worn items.

Step‑by‑Step Dyeing & Aftercare

Follow these steps to correctly dye your leather, seal the finish, and maintain the color and condition for long-term results.

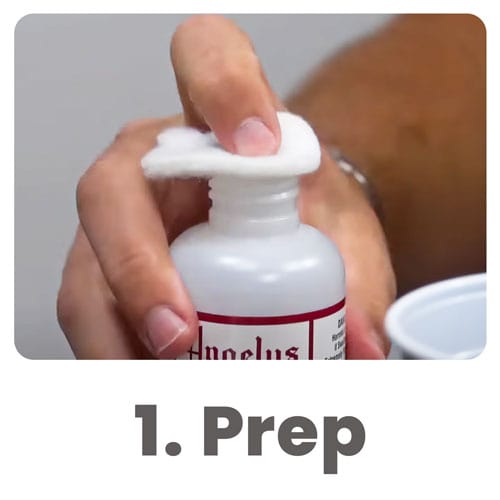

1. Preparation

Begin by cleaning the leather to remove factory coatings, oils, and waxes.

Using Angelus leather preparer and deglazer ensures the surface is ready to absorb dye. If the leather has a glossy finish, lightly sanding the area can help improve absorption.

Just make sure to always work in a well-ventilated area, wear gloves to protect your hands, and remember that proper preparation lays the foundation for an even, long-lasting dye job.

2. Application of Dye

Once the surface is clean, apply the leather dye using a wool dauber in smooth, circular motions. This technique promotes consistent coverage.

Begin with a thin first coat and allow it to dry completely before adding another layer. Building up color gradually helps you reach the desired shade while avoiding streaks.

For detailed areas or small sections, dye pen applicators offer added precision and control.

3. Removing Excess Surface Dye

After the final coat has dried, gently buff the surface using a clean microfiber cloth. This removes any loose dye and smooths out the finish. If you notice remaining residue, use a cloth dampened slightly with rubbing alcohol to wipe the surface.

Furthermore, avoid soaking the leather, as excessive moisture can cause the color to fade. This step helps prevent dye transfer and improves the feel of the leather.

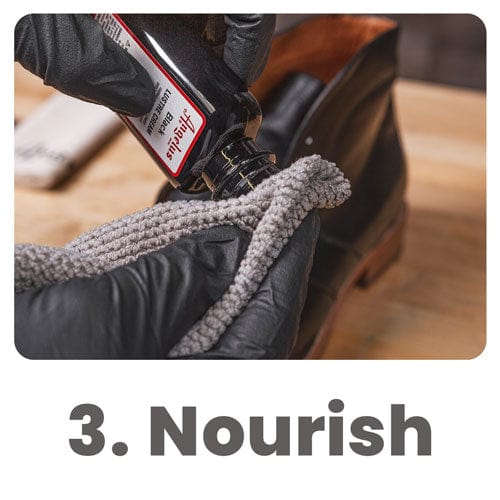

4. Sealing & Conditioning

To retain the natural feel of the leather, we recommend conditioning or applying wax. Conditioning helps restore softness and flexibility, especially for high-use leather items like footwear, belts, or furniture.

Optionally, you may apply an acrylic finisher once the dye has set. While sealing makes the leather water-repellent, it can also alter its original texture.

5. Aftercare

To keep your dyed leather in good condition, regular maintenance is required. Clean gently with leather soap to remove dirt without stripping the finish. Then, apply a leather balm or leather conditioner to preserve moisture and prevent drying.

To reduce fading, limit sun exposure and allow freshly dyed items to cure fully before heavy use. Proper aftercare helps maintain the vibrancy of color and extends the life of your leather goods.

Ready to Transform Your Leather?

From restoring worn leather to creating a bold custom color, the right dye makes all the difference. Angelus Direct offers professional-grade options, fast U.S. shipping, and trusted tools for clean, even results.

Explore every dye product in one place and get everything you need to start your next project with confidence.

Frequently Asked Questions

What Dye Works Best on Leather?

Alcohol-based leather dye works best on most smooth leather surfaces. It penetrates deeply, provides rich color, and dries quickly for reliable results.

Can You Permanently Dye Leather?

Yes, leather can be permanently dyed. Once absorbed into the fibers and properly sealed, the color will not wash off or fade easily.

Will Leather Dye Rub Off?

Leather dye may rub off if excess dye is not removed or the surface is left unsealed. Buffing and sealing reduce this risk and help set the color.

Is It Safe to Re‑Dye Finished Leather?

Yes, it is safe to re-dye finished leather after proper preparation. Removing existing finishes allows the new dye to bond more effectively with the material.

Other collections and products:

Leather Paint | White Leather Paint | Pearlescent Paint | Shoe Laces | Suede Dye | Shoe Cleaner | Shoe Wax | Rope Laces | Shoe Polish | Dye Products | Shoe Customization Kit Shoe Paint Kit | Mink Oil | Midsole Paint | Paint Duller | Angelus 2 Soft | Fabric Dye | Urethane Clear Coat | Angelus Best Sellers